Plastic Extrusion For Utility Systems | Accord Utility System

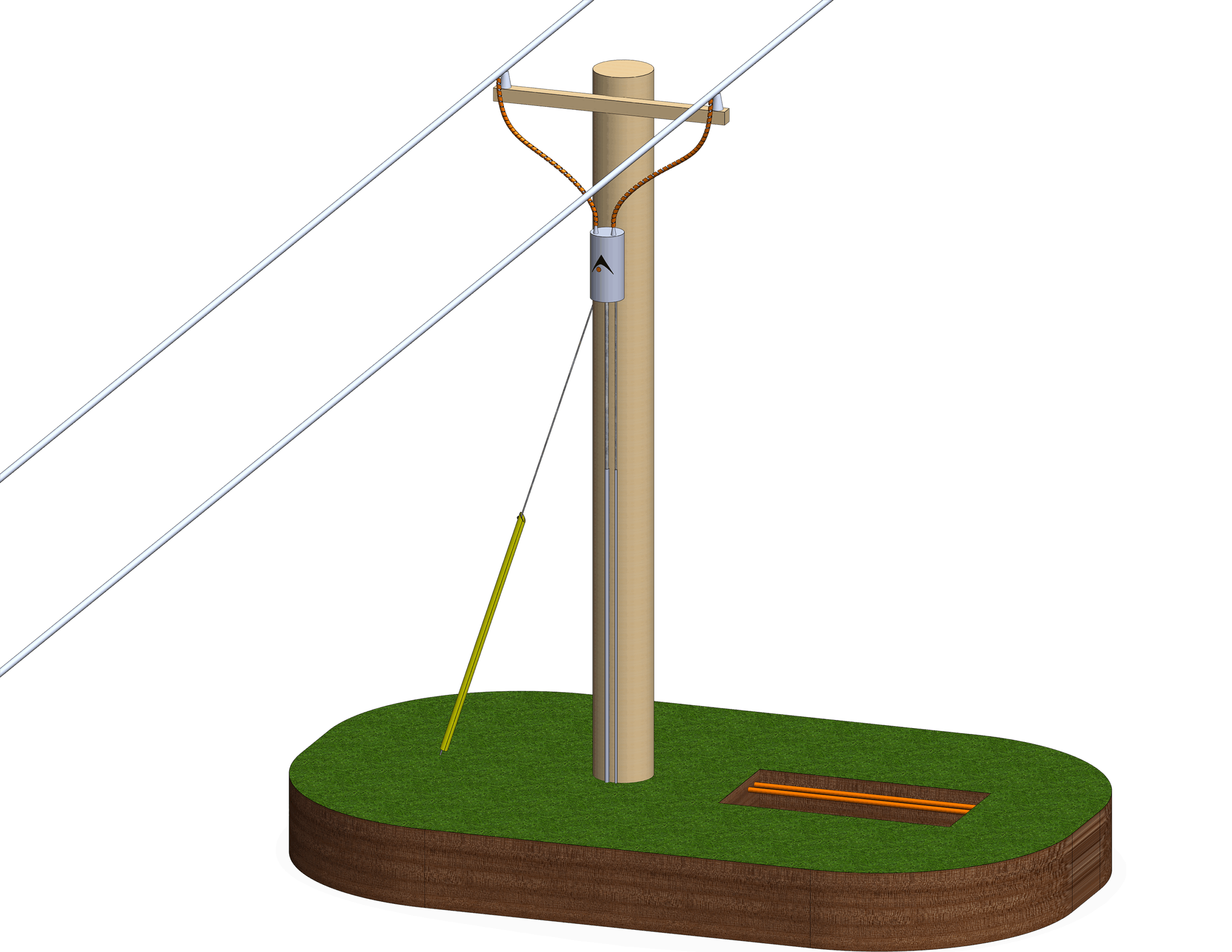

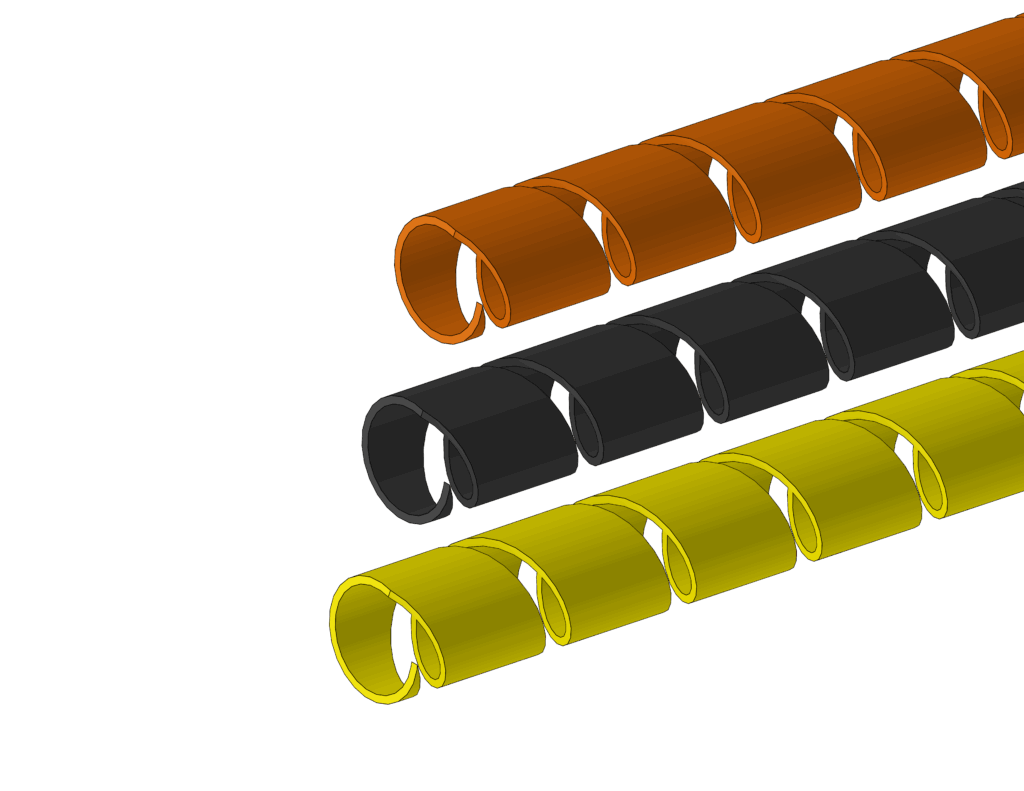

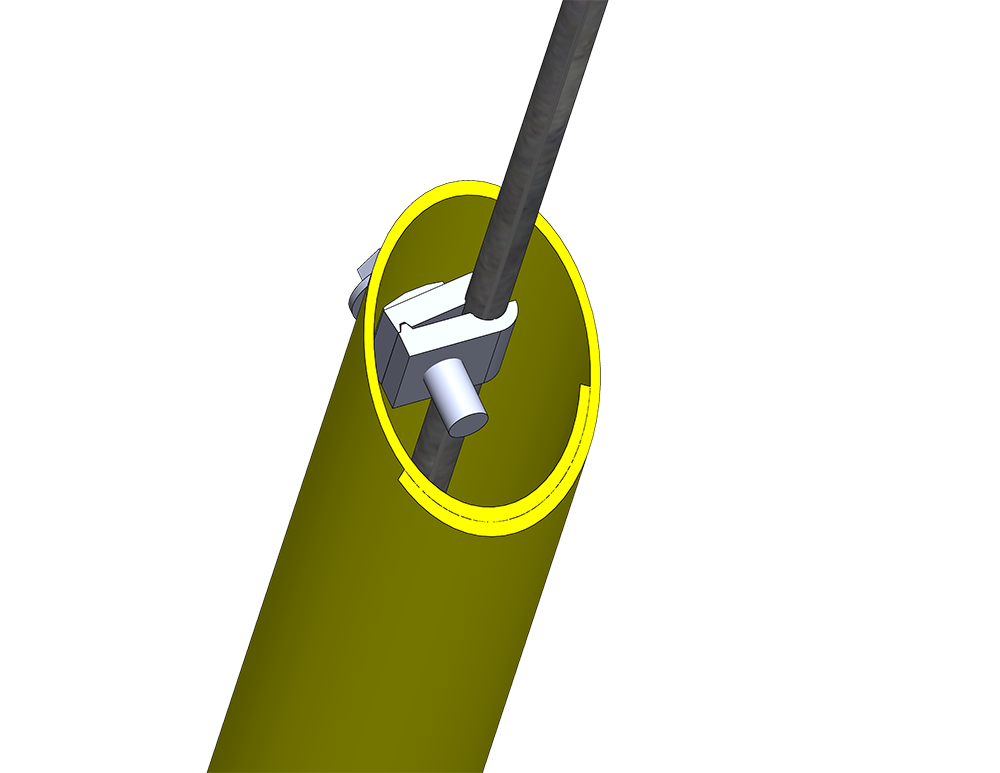

Plastic extrusion for utility systems is the focus of Accord Utility Systems, the utility division of Accord Plastics. We make strong and reliable products like guy guards, cable guards, spiral wraps, and ground wire molding for utility providers and contractors across North America.

With over 35 years of experience, we deliver products that are made with care and built to last. Our team is known for good support and precise work. As a leader in plastic extrusion and innovation, we help protect the important infrastructure that keeps communities running.

Trusted in the Utility Industry

With over 35 years of manufacturing experience, Accord Utility Systems has built a strong reputation for being reliable and precise. Our team understands what utility companies need, so we design each part to work well even in tough conditions.

Every product we make goes through a careful extrusion process to make sure it stays strong and consistent. This process involves heating raw plastic until it becomes molten plastic, then shaping it through a custom die. Once it cools, the finished extruded plastic is tough, long-lasting, and ready for heavy use.

We’re proud to be one of the most trusted names in custom plastic extrusion across Canada and the United States. From small contractors to big utility companies, our partners depend on our high-quality materials and cost-effective products to protect and support the systems that power communities.

Why Choose Accord Utility Systems?

1. High-Quality Manufacturing

At Accord Utility Systems, we focus on making products that last. Our extrusion process is checked carefully at every step to make sure everything meets the highest standards. We only use strong, high-quality resins and polymers that can handle tough weather and heavy use.

Each plastic profile we create is tested for strength, flexibility, and color. Because of this, our products stay strong even in very hot, cold, or sunny conditions.

2. Custom Plastic Extrusion Options

We understand that every project is unique. That’s why we offer custom plastic extrusion to match your exact needs. Whether you need special custom shapes, colors, or sizes, our engineers can adjust the process involves to create the perfect product for your system.

We use special molds and tools to form extruded plastic into tubes, guards, and wraps that fit perfectly. This makes it easy to get parts that match your project’s design, safety, and performance needs.

3. Cost-Effective and Scalable Solutions

Our plastic extrusion for utility systems gives you high strength at a cost effective price. Since we can make high volume parts quickly and efficiently, we keep prices low without lowering quality.

No matter how big or small your order is, our factory can handle it. We can make thousands of parts fast while keeping every one consistent and durable.

4. Innovation and Expertise

With over 35 years of experience, we keep improving our extrusion process to make products that perform better every year. Our team knows the latest techniques in injection molding, plastic tubing, and extrusion technology, helping us create better and safer solutions.

From insulation and protection to custom shapes and modern materials, we’re always looking for new ways to improve plastic extrusion for utility systems and meet the needs of today’s industry.

Our Product Line

With over 35 years of manufacturing experience, Accord Utility Systems has built a strong reputation for being reliable and precise. Our team understands what utility companies need, so we design each part to work well even in tough conditions.

Every product we make goes through a careful extrusion process to make sure it stays strong and consistent. This process involves heating raw plastic until it becomes molten plastic, then shaping it through a custom die. Once it cools, the finished extruded plastic is tough, long-lasting, and ready for heavy use.

We’re proud to be one of the most trusted names in custom plastic extrusion across Canada and the United States. From small contractors to big utility companies, our partners depend on our high-quality materials and cost-effective products to protect and support the systems that power communities.

Guy Guard

Multiple Profiles, mounting hardware, and colour options Available

(Custom guards available upon request)

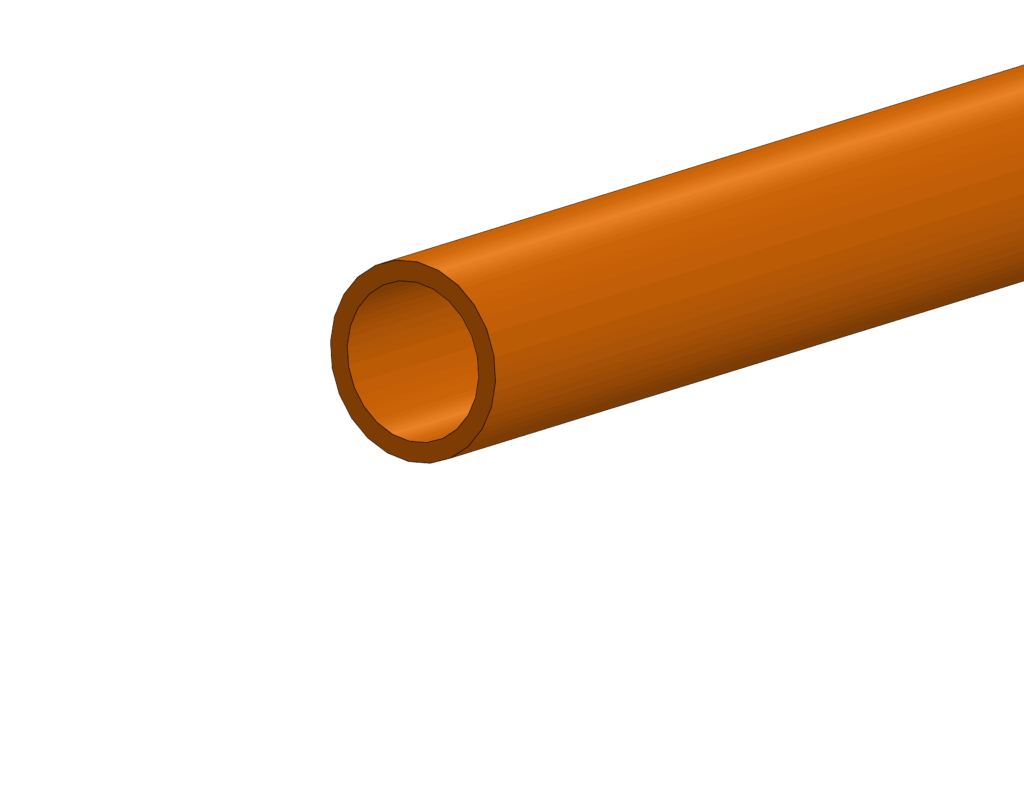

Pipe Guard

A heavy-duty protective cover designed to shield exposed utility pipes from accidental impact

Why Plastic Extrusion Is the Best Choice?

Plastic extrusion has many advantages compared to other manufacturing methods like injection molding.

Efficiency: The continuous extrusion process makes it easy to create long, even parts without stopping production.

Durability: Extruded plastic parts are strong, resist rust, corrosion, and sunlight damage better than metal, and their production is monitored through the Federal Plastics Registry to support quality and sustainable use.

Customization: We can design custom shapes, sizes, and colors to match your needs.

Affordability: This method is very cost effective, especially when producing high volume orders.

Flexibility: Products like plastic tubing, wraps, and guards can be made for different uses and environments.

That’s why plastic extrusion for utility systems is the top choice for industries that need materials that are reliable, long-lasting, and easy to customize.

Our Commitment to Quality and Support

At Accord Utility Systems, we believe that strong relationships are just as important as strong products. Our friendly support team works closely with every customer to make sure each part we make fits their needs perfectly.

We follow high-quality standards from start to finish. Every item goes through careful checks and tests to make sure it meets our goals for strength, color, and flexibility.

We also stay in touch with our customers at every step. Whether you need help choosing the right materials, creating custom shapes, or planning high-volume production, our team is always ready to help.

Partner with Accord Utility Systems

If you need a trusted partner for plastic extrusion for utility systems, Accord Utility Systems is here for you. With our skills in custom plastic extrusion, cost-effective designs, and large-scale production, we can help you finish your project on time and within your budget.

From plastic tubing and cable guards to injection molding and other extruded plastic parts, we make sure you get reliable products every time.

Contact us today to learn more about our extrusion process, products, or pricing. Together, we’ll create strong, high-quality solutions that give long-lasting insulation and protection for your utility systems.

FAQs

What is plastic extrusion for utility systems?

Plastic extrusion for utility systems is a process where molten plastic is shaped into long parts like tubes, wraps, and guards. These parts help protect cables, pipes, and wires used in power and utility projects.

How does the extrusion process work?

The process involves melting raw plastic and pushing it through a shaped mold to form extruded plastic parts. Once cooled, these parts are cut into custom shapes ready for use.

Why are custom plastic extrusion products important?

Custom plastic extrusion lets you choose the size, color, and shape that fit your project best. It helps make parts that work better and last longer for specific needs.

What are the benefits of using extruded plastic?

Extruded plastic is strong, lightweight, and cost effective. It also resists water, rust, and sunlight, making it great for outdoor use and insulation and protection.

What types of products are made through plastic extrusion?

We make many plastic profiles like spiral wraps, wire molding, and plastic tubing. Each one is designed to protect and organize important utility parts safely.