TWIN SCREW EXTRUSION

Enhancing Plastic Manufacturing

Twin-screw extrusion is a remarkable manufacturing method that combines two interlocking screws rotating inside a heated barrel. This clever design significantly improves mixing and blending, making it ideal for various applications like thermoplastics and specialty polymers. It also provides excellent temperature control and material integration, which is crucial for producing high-quality products.

At Accord Plastics, we’re thrilled to embrace this technology to craft complex profiles and custom formulations tailored to the diverse needs of industries such as automotive, food packaging, and pharmaceuticals. Twin-screw extrusion’s versatility allows for quickly incorporating additives, fillers, and even recycled materials, positioning it as a great eco-friendly option for many manufacturers.

Our dedicated engineering team brings over 50 years of experience optimizing the twin-screw extrusion process. We can produce more oversized items without sacrificing quality with state-of-the-art machinery and innovative techniques. We take pride in understanding our clients’ needs and ability to adapt to changing market demands, highlighting the value of twin-screw extrusion in providing tailored solutions. This process not only enhances efficiency and reduces waste but also boosts the mechanical properties of the final products, making it a top choice in the competitive landscape of plastic manufacturing.

What we’ve done

Extrusion Lines

We operate 14 advanced extrusion lines, producing higher volume. This leads to increased versatility in handling different types of plastics. All of the lines are in place to ensure strong results.

Strategic Sites

We have two production sites, which optimize distribution and decrease wait times for production. This allows customers of all locations to be served effectively.

Successful Projects

Thousands of successful projects have been done for our clientele, consistently delivering products on time with high-quality results.

Engaged Customers

We are proudly serving over 200 customers. We focus on long-term relationships through our vital customer service. We continuously deliver tailored solutions that are dependent on our customers’ needs.

Why Choose Accord Plastics Corp for Twin Screw Extrusion?

Choosing the right company for twin screw extrusion is important when you need strong, accurate, and high quality plastic products. At Accord Plastics Corp, we bring over 35 years of experience in custom plastic extrusion. We understand how to take an idea and turn it into a real product that performs well in everyday use. Our team works with many industries, including automotive, food packaging, medical, and consumer goods.

We use a full extrusion system that includes advanced machines, skilled staff, and a controlled process. This helps us create products quickly without losing quality. Our goal is to provide fast service, fair pricing, and reliable results for every customer, while supporting plastic waste and pollution reduction through efficient production and responsible material use.

Advanced Control Over Heating and Cooling

Our twin screw extrusion process uses smart heating and cooling controls. Each step is carefully monitored to make sure the plastic melts evenly and then cools down at the right time. This keeps the shape strong and clean. Heating and cooling are important, because they affect how the final product looks and how well it performs. Proper temperature control helps prevent cracks, weak spots, and mistakes.

A Complete and Reliable Extrusion System

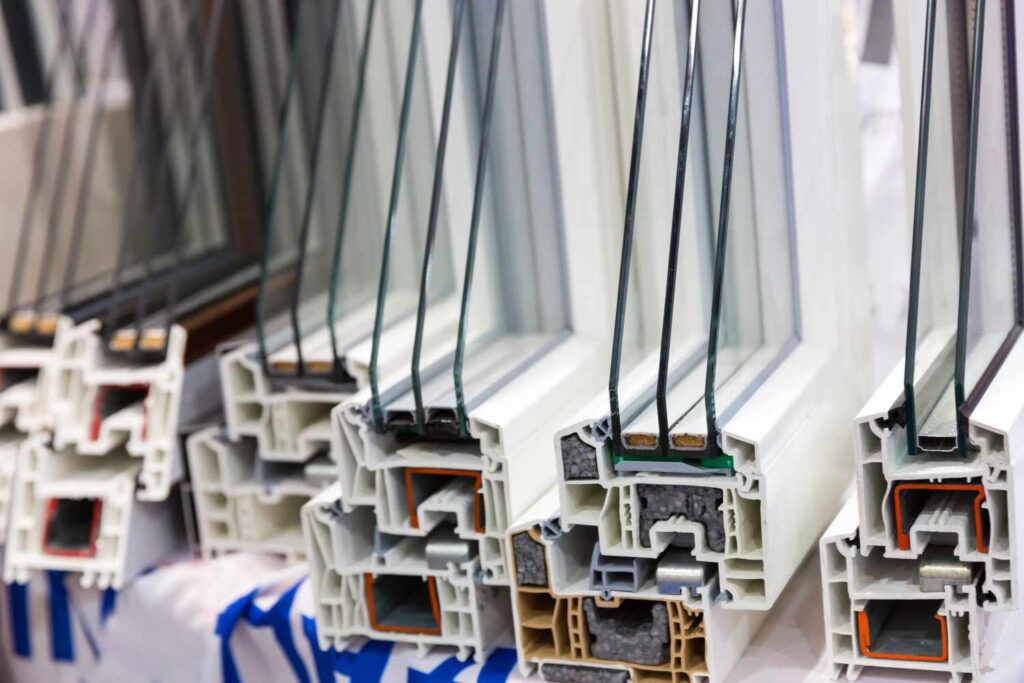

We operate a full extrusion system that includes feeding equipment, twin screw extruders, shaping dies, and downstream equipment. The system also includes important parts such as barrel sections, screw elements, and temperature zones. Each part has a job that helps turn raw materials into a finished product. With our automated setup, we can work faster and produce consistent results.

Adjusting Screw Speeds for Quality

Different plastics need different processing requirements. This is why we adjust screw speeds based on the material and the final shape our customer needs. Faster screw speeds help mix and melt materials quickly. Slower speeds help with detailed shaping and smooth surfaces. By changing screw speeds when needed, we can improve product strength, color, and finish.

Matching Processing Requirements With Barrel Sections

Our machines include several barrel sections, and each section can be heated or cooled separately. This allows us to match the processing requirements of each material. For example, soft plastics may need lower heat, while tougher materials need higher temperatures. With this level of control, we can create products that are strong, smooth, and consistent.

FAQs

What is twin screw extrusion?

Twin screw extrusion is a method that uses two screws turning together to mix and shape plastic. This extrusion process helps create strong, smooth, and custom plastic parts.

How is twin screw extrusion different from single screw extruders?

Single screw extruders use only one screw and are best for simple jobs. Twin screw extruders mix better and work with a wide range of materials and shapes.

What types of twin screw extruders do you use?

We use different types of twin screw extruders like parallel and counter rotating machines. These help us match the right machine to the product and improve quality.

What materials can be used in your extrusion process?

We work with a wide range of plastics, including soft and hard materials. Each material is matched to the best screw speed and temperature settings for top results.

Why are barrel sections important in the extrusion system?

Barrel sections help control heating and mixing at different stages of the process. This helps us meet exact processing requirements for each product.