When it comes to developing custom plastic components for your product or system, selecting the right plastic extrusion company can make or break your project. With many suppliers across Canada offering a range of capabilities, it’s critical to evaluate potential partners based on technical expertise, manufacturing capacity, quality standards, and customer service.

Whether you’re in construction, automotive, furniture, marine, retail, or industrial manufacturing, this guide will walk you through the essential factors to consider when choosing a Canadian plastic extrusion company for your custom extrusion needs.

Why Custom Plastic Extrusion Matters

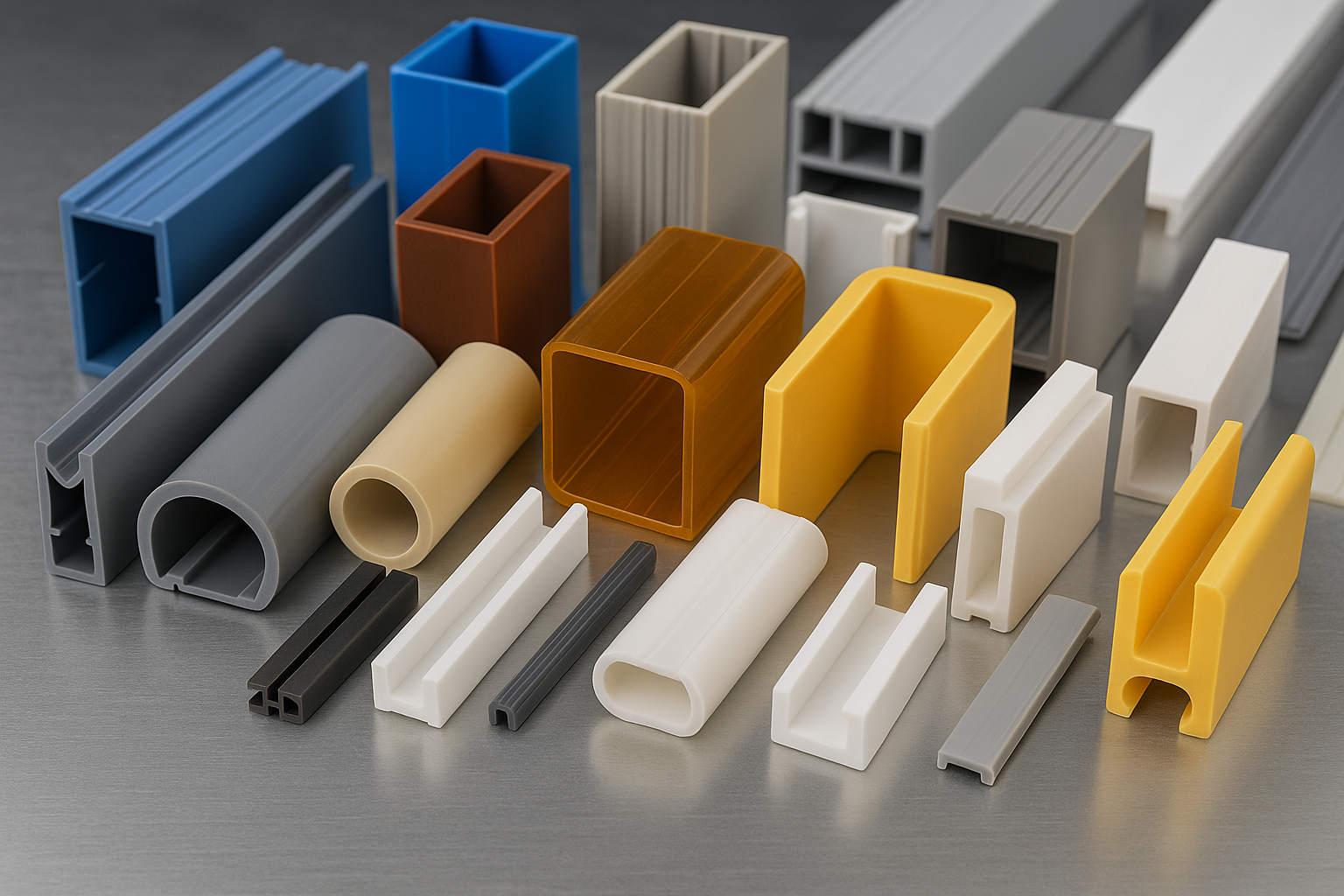

Plastic extrusion is a manufacturing process where melted plastic is forced through a die to form a continuous profile with a specific cross-section. When custom-designed, these profiles can improve product functionality, aesthetics, and ease of assembly while reducing costs and material waste. Choosing the right plastic extrusion company ensures that this process is optimized to meet your specific project requirements, resulting in greater efficiency and product quality.

Custom extrusions are often used in:

- Window and door systems

- Wire channels and gaskets

- Automotive trim

- Furniture edgebanding

- Marine hatch seals

- POP display components

Choosing the right partner for custom plastic extrusion means ensuring your unique product requirements are met with precision and efficiency.

1. Evaluate Technical Capabilities

The first and most important step is understanding what the extrusion company is capable of producing. Not all extruders offer the same services or handle the same materials.

Key Questions to Ask:

- What types of profiles can they extrude? (e.g., hollow, solid, complex geometries)

- Do they offer single, co-, or tri-extrusion?

- Can they process the materials your project requires?

- Do they offer in-house tooling design and prototyping?

Advanced extrusion companies offer full design support, helping you turn a sketch or CAD file into a finished part, with optimized material selection and die design.

2. Assess Material Expertise

Different plastic materials offer different performance characteristics. A quality extrusion partner should have expertise in selecting and processing a wide range of thermoplastics, such as:

- Rigid & Flexible PVC – Durable, affordable, weather-resistant

- ABS – Tough and impact-resistant

- Polypropylene (PP) – Lightweight and chemically resistant

- Polyethylene (PE) – Economical and moisture-resistant

- TPV/TPE – Flexible, rubber-like thermoplastics used in seals and gaskets

Choosing a company that understands the material science behind extrusion ensures your product will perform in its intended environment.

3. Review Manufacturing Capacity & Lead Times

If your project requires consistent, high-volume production, capacity matters. Look for a company that:

- Has multiple extrusion lines

- Offers fast changeovers between runs

- Can scale from prototypes to large orders

- Maintains strong inventory control

Ask about typical lead times for tooling, sampling, and production. Canadian companies with in-house tooling often offer shorter timelines than those who outsource.

4. Consider Customization & Secondary Services

The right extrusion partner should do more than just extrude. Look for value-added services that reduce the need for post-processing at your facility:

- Cut-to-length and punching

- Embossing or printing

- Adhesive tape application

- Laminating or co-extrusion with decorative finishes

- Drilling, notching, or bending

These services not only save time and labor but can also improve product consistency and reduce logistics complexity. By integrating secondary operations into the extrusion process, manufacturers can minimize the number of vendors involved and streamline production workflows. This integration also helps ensure better quality control and reduces the chances of delays or errors during assembly.

5. Ask About Quality Assurance

In manufacturing, quality is non-negotiable. A reliable extrusion company will have quality controls in place at every stage, including:

- Raw material inspection

- In-process monitoring and dimensional checks

- Final inspection before shipping

Look for certifications (e.g., ISO 9001) or evidence of continuous improvement programs. A reputable plastic extrusion company should demonstrate a strong commitment to quality, especially when serving regulated industries (e.g., automotive or construction) that are often held to higher standards.

6. Evaluate Communication & Customer Support

Good communication is critical in custom manufacturing. Clear and open dialogue can prevent costly misunderstandings and accelerate problem-solving during production. Choose a company that:

- Is responsive and transparent

- Offers dedicated account managers or project coordinators

- Provides regular updates on order status

- Takes time to understand your technical requirements

A collaborative, service-oriented partner is more likely to deliver a smooth and successful project from design through delivery.

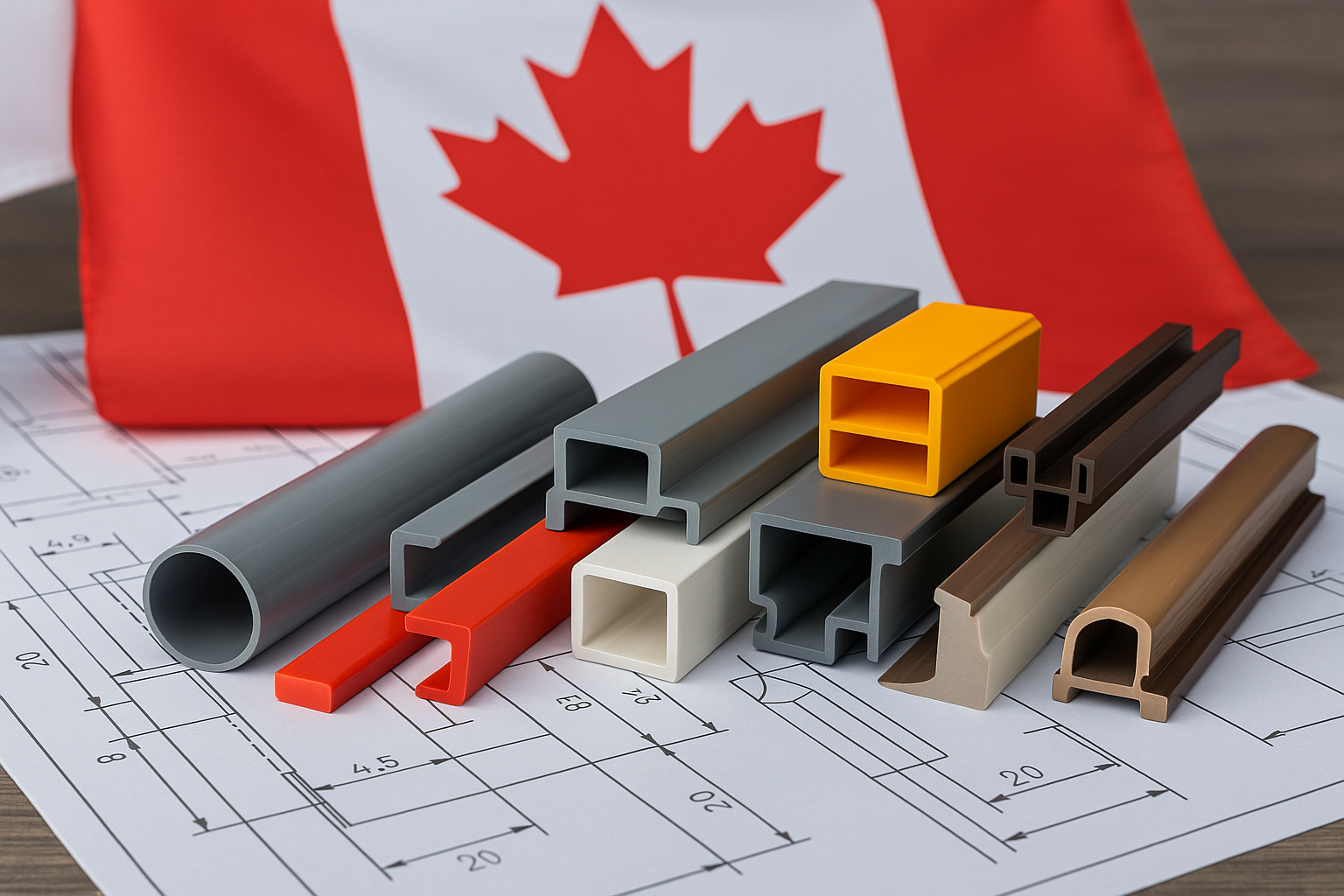

7. Prioritize Location & Logistics

Working with a plastic extrusion company based in Canada offers several advantages:

- Faster shipping times and reduced freight costs

- Easier face-to-face collaboration if needed

- No cross-border duties or international shipping delays

- Alignment with Canadian regulations and standards

Choosing a local partner also supports domestic manufacturing and sustainability goals.

8. Review Past Work and Industries Served

A reputable plastic extrusion company should be able to share case studies, references, or examples of past projects. This helps you assess:

- Their ability to solve complex extrusion challenges

- Experience with similar applications or industries

- Long-term relationships with clients

Industry versatility is a plus—companies that serve multiple sectors are often more adaptable and technically skilled.

9. Understand Their Quoting Process

Transparency in quoting is a good sign of a reliable extrusion partner. A comprehensive quote should include:

- Tooling costs and lead time

- Per-foot or per-piece pricing at different volumes

- Material recommendations

- Additional fees for secondary operations

If pricing isn’t clear, or if a company avoids answering questions about cost breakdowns, consider it a red flag.

10. Consider Sustainability Practices

Sustainability is becoming a priority in all areas of manufacturing. Ask about:

- Use of recycled materials

- In-house regrinding and scrap reuse

- Efficient manufacturing processes that reduce waste

- Commitment to environmental standards or green certifications

Environmentally responsible extrusion partners can help you meet your own corporate sustainability goals. These companies often take a proactive role in reducing environmental impact by investing in energy-efficient equipment and sustainable sourcing practices. Their commitment to green manufacturing can also enhance your brand’s reputation and align with consumer expectations for eco-friendly products.

Final Thoughts

Choosing the right plastic extrusion company in Canada is about more than just cost—it’s about finding a partner that understands your needs and can deliver consistent, high-quality results. Evaluate potential suppliers based on their technical capabilities, material knowledge, quality systems, and communication. Prioritize companies that offer full-service solutions, fast lead times, and a proven track record across industries.

By taking the time to vet your extrusion partner properly, you set your custom project up for long-term success.

Need help defining your extrusion requirements? Start by outlining your material needs, profile dimensions, performance goals, and target lead times. From there, begin conversations with top Canadian extrusion providers who align with your expectations for quality, service, and innovation.