In today’s fast-paced and competitive manufacturing environment, companies across Canada are seeking efficient, scalable, and cost-effective ways to bring their product designs to life. For many, custom plastic extrusion provides the perfect solution. From automotive and construction to furniture and retail displays, plastic extrusion is a versatile process that delivers consistent, high-quality components at scale.

At Accord Plastics, based in Vaughan, Ontario, we specialize in custom plastic extrusion services that are tailored to meet the specific requirements of businesses across the country. With decades of experience and state-of-the-art extrusion lines, we help Canadian industries innovate and grow with precision-engineered plastic profiles.

In this article, we’ll explore what custom plastic extrusion is, why it’s important, and how it provides industry-specific solutions nationwide.

What Is Custom Plastic Extrusion?

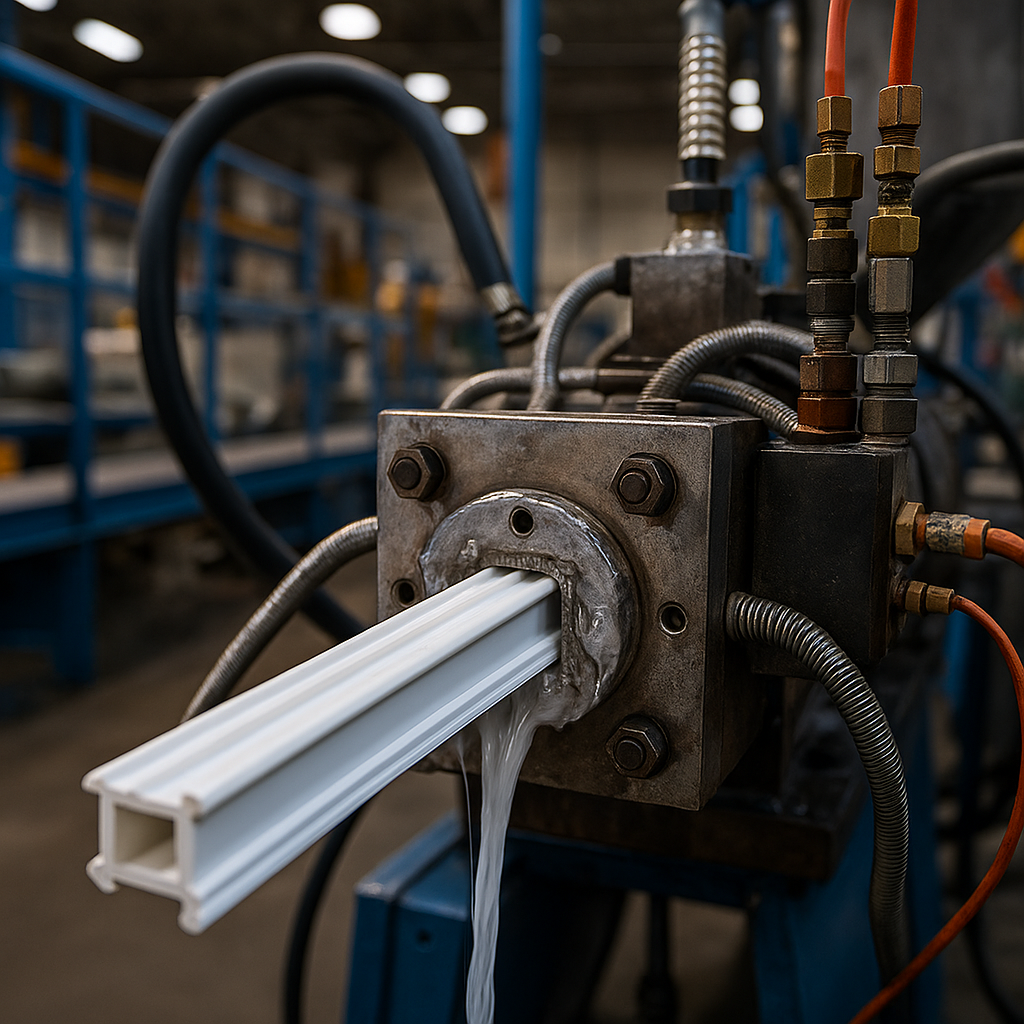

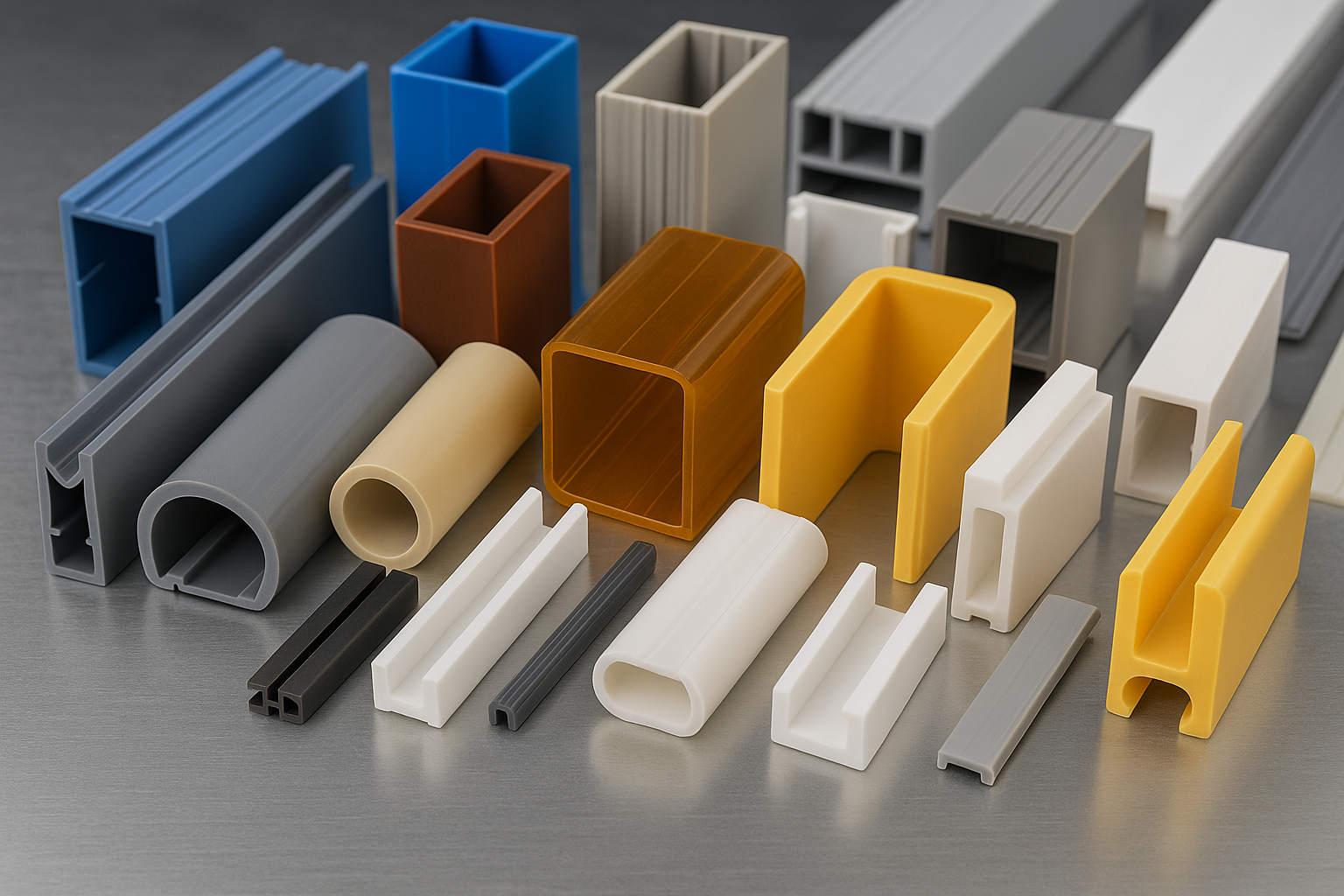

Plastic extrusion is a manufacturing process that involves melting raw plastic materials and forcing them through a die to create continuous profiles of a specific shape. The result can be anything from rigid plastic trims and tubes to flexible seals and complex co-extruded parts.

Custom plastic extrusion goes beyond standard profiles by offering personalized solutions designed to exact specifications. Whether you need a unique shape, specific material properties, or secondary operations like punching, cutting, or taping, custom extrusion allows for tailored outputs that fit your application perfectly.

Advantages of Custom Plastic Extrusion:

- Design flexibility

- Material customization (e.g., PVC, ABS, polyethylene)

- Consistent quality across high-volume production

- Cost-effectiveness over traditional machining for long runs

- Ability to include value-added services like lamination, printing, or adhesive application

Why Canadian Companies Choose Custom Extrusion

Across Canada, manufacturers in various sectors require components that offer performance, durability, and aesthetic appeal. Custom plastic extrusion provides the design freedom and scalability to support both prototyping and full production runs.

Key reasons why businesses in Canada choose custom plastic extrusion include:

- Local Manufacturing: Partnering with a Canadian supplier like Accord Plastics reduces lead times, avoids international shipping costs, and simplifies quality control.

- Regulatory Compliance: Canadian manufacturers must adhere to specific standards (e.g., CSA, building codes). Custom extrusions ensure compliance with dimensional and material specs.

- Sustainability: Many companies are now prioritizing sustainable sourcing. At Accord, we incorporate recycled materials where possible and operate an in-house recycling program.

Industries We Serve with Custom Plastic Profiles

Custom plastic extrusion is not limited to one niche. It’s a core component for industries that require form, function, and consistency in their parts. Here’s how various sectors across Canada benefit from custom extruded plastic profiles:

1. Automotive

From interior trims to wiring channels, automotive manufacturers rely on precision-molded plastic parts that are lightweight, durable, and visually consistent. Accord Plastics supplies custom extrusions used in door panels, seals, spacers, and more.

2. Furniture & Office Interiors

Custom profiles are essential for components like edgebanding, cable channels, desk trims, and corner guards. We work with office and retail furniture designers to produce profiles that match their brand aesthetics and durability standards.

3. Construction & Fenestration

PVC extrusions are widely used in windows, doors, and weatherstripping. Accord delivers co-extruded profiles with UV-resistant capstocks or foam fillers for insulation, helping Canadian building product manufacturers meet energy efficiency goals.

4. Marine & RV

Extruded profiles for marine and recreational vehicles need to withstand temperature changes, moisture, and wear. We supply flexible and rigid components like moldings, seals, and mounting trims tailored for these environments.

5. Retail Displays & POP

Point-of-purchase (POP) displays often require plastic profiles that combine function and visual appeal. Our custom extrusion services help retailers and packaging companies create attention-grabbing displays with integrated lighting channels, sign holders, and edge trims.

Materials for Custom Plastic Extrusion

One of the most important aspects of extrusion is selecting the right material. At Accord Plastics, we offer expertise in working with a wide variety of thermoplastics:

- Rigid & Flexible PVC – Ideal for construction, signage, and weatherstripping

- ABS – Strong and impact-resistant, used in furniture and consumer products

- Polyethylene (PE) – Lightweight and cost-effective for tubing and general applications

- Polypropylene (PP) – Good chemical resistance, common in packaging and automotive

- TPV/TPE – Flexible rubber-like materials used in seals and gaskets

We help our clients choose the optimal resin based on their performance, appearance, and cost requirements.

Customization Options & Value-Added Services

The value of custom extrusion lies in how well the profile can be adapted to your product’s needs. At Accord Plastics, we offer a variety of customization options:

1. Profile Design

Our engineering team works with your specifications (or assists in developing new designs) to create a custom die for your unique shape.

2. Color Matching

We provide exact color matching using masterbatch technologies or capstock co-extrusion to meet branding or visibility needs.

3. Laminating & Taping

Profiles can be laminated with decorative foils or woodgrain films, or integrated with adhesive tapes for easy mounting.

4. Secondary Operations

We offer cut-to-length, drilling, punching, notching, and embossing – so your components arrive ready for assembly.

5. Co-Extrusion & Tri-Extrusion

Need a profile with two or more materials? Our advanced lines support multi-layer extrusion, combining rigidity and flexibility in a single part.

Canadian-Made Quality You Can Trust

As a proudly Canadian plastic extrusion company, Accord Plastics is committed to delivering high-quality, custom solutions that meet the unique demands of our domestic market. Our Vaughan, Ontario facility operates 14 extrusion lines and in-house tooling for rapid prototyping and scalable production.

We understand the importance of reliability, on-time delivery, and consistent quality for Canadian manufacturers. Whether you need 1,000 feet or 1 million, we’re ready to help you turn your concept into reality.

How to Get Started with Custom Extrusion

Working with Accord Plastics on a custom extrusion project is simple:

- Share Your Concept: Send us a sketch, CAD drawing, or product sample.

- Material & Design Review: We’ll help you choose the best material and refine your design.

- Tooling & Sampling: We create your custom die and produce samples for testing.

- Production & Delivery: Once approved, we begin production with full quality assurance.

Whether you’re launching a new product or improving an existing design, custom extrusion helps you achieve performance, efficiency, and aesthetics tailored to your market.

Conclusion

Custom plastic extrusion is a cornerstone of Canadian manufacturing, enabling companies to create tailored solutions for everything from building materials to retail displays. With the ability to control shape, material, and finish, extruded plastic profiles are helping businesses reduce costs, streamline production, and enhance product performance.

If you’re looking for a trusted plastic extrusion company in Canada, Accord Plastics offers the experience, capabilities, and service to bring your vision to life. Contact our team today to discuss your next project.

Interested in custom plastic extrusion solutions? Contact us today or learn more about our manufacturing process.