Windows and Doors using Plastic Extrusion has become a defining technology in modern fenestration systems, especially in the creation of windows and doors. As builders and homeowners alike strive for energy efficiency, aesthetic appeal, and long-term durability, plastic extrusion provides a solution that checks all the boxes. The process, which forms continuous profiles from thermoplastic materials, has transformed the building materials market by offering customizable, reliable, and cost-effective components.

The Basics of Plastic Extrusion for Windows and Doors

What is Plastic Extrusion?

Plastic extrusion is a high-volume manufacturing method where raw plastic is melted and shaped into continuous profiles. These profiles are then cut to size and used in various applications—none more prominent than in windows and doors.

Key Applications

- Window frames

- Door frames

- Sealing profiles

- Mullions and transoms

Why Plastic Extrusion is Ideal for Modern Construction?

Energy Efficiency

The multi-chamber design of extruded plastic profiles ensures superior thermal insulation, cutting down energy consumption in homes and commercial buildings.

Corrosion Resistance

Plastic extrusion materials like PVC do not corrode, unlike their metal counterparts, making them perfect for humid and coastal environments.

Key Materials Used in Plastic Extrusion

PVC: The Industry Standard

Polyvinyl chloride (PVC) is the most common material due to its balance of flexibility, durability, and cost-effectiveness.

Other Emerging Materials

- Thermoplastic elastomers (TPEs)

- Acrylonitrile butadiene styrene (ABS)

- Composite blends for enhanced properties

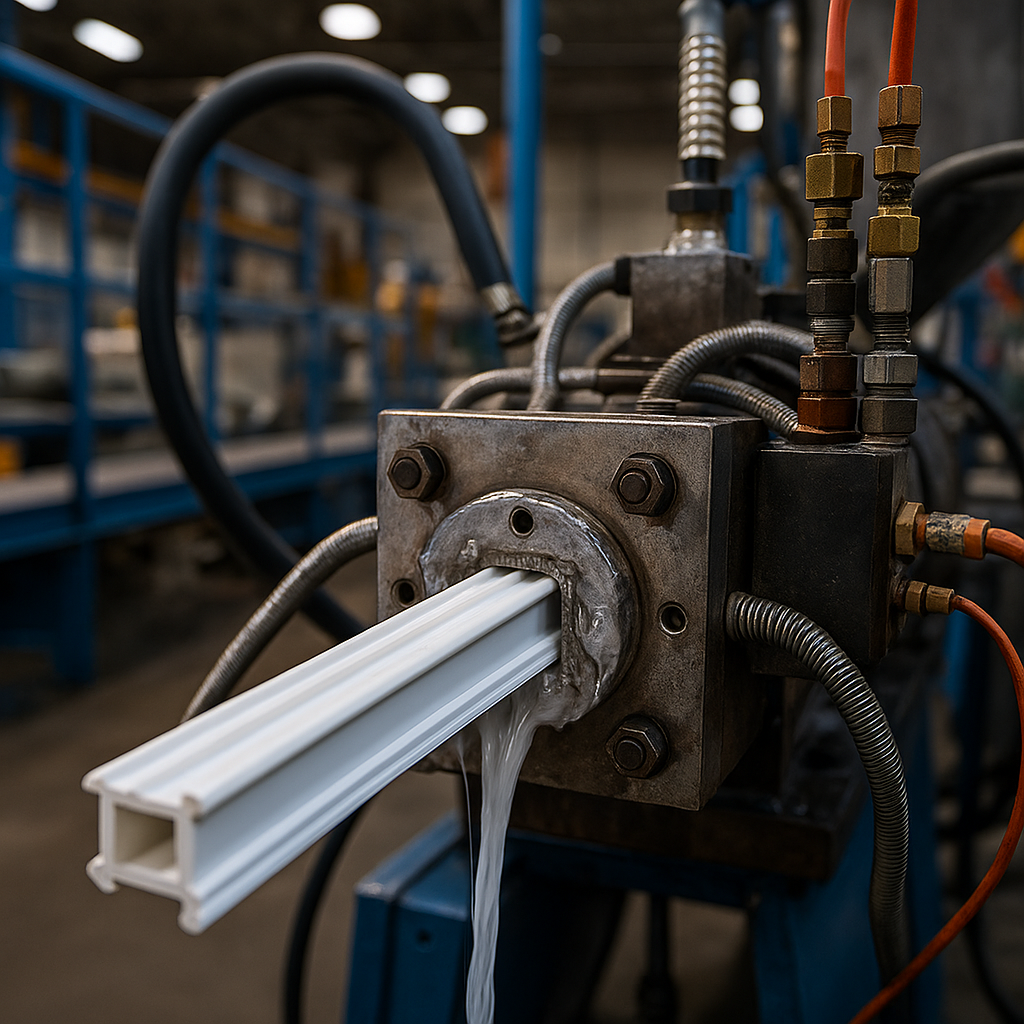

The Plastic Extrusion Process Explained

Step 1: Feeding and Melting

Plastic pellets are fed into a heated barrel where they melt into a viscous fluid.

Step 2: Shaping Through the Die

The molten plastic is pushed through a custom-shaped die that defines the profile’s cross-section.

Step 3: Cooling and Cutting

The profile is cooled—usually with water baths—and then cut into desired lengths for final processing.

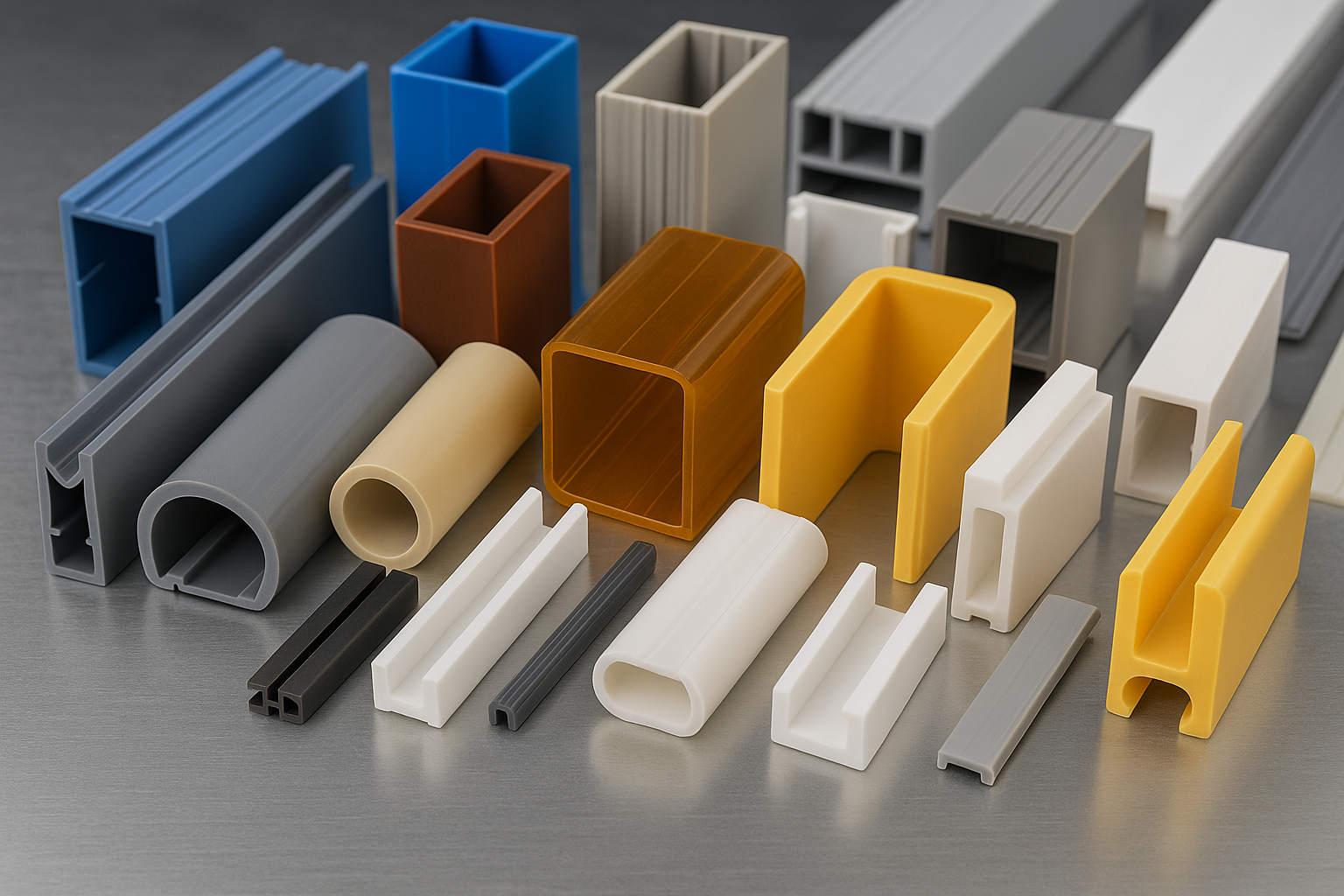

Types of Plastic Profiles for Windows and Doors

Solid Profiles

Strong and simple, these profiles are used where robustness is essential.

Hollow Multi-Chamber Profiles

These offer superior insulation and are common in energy-efficient window systems.

Co-Extruded Profiles

Combining two materials in one process, these profiles bring together different performance characteristics in a single product.

Comparing Plastic Extrusion with Traditional Materials

Plastic vs. Wood

Plastic is rot-resistant and requires less maintenance than wood.

Plastic vs. Aluminum

Plastic provides better thermal insulation, though aluminum offers higher strength.

Benefits of Plastic Extrusion in Door and Window Manufacturing

- Lightweight and easy to install

- Customizable in color, finish, and texture

- Capable of incorporating recycled materials

- Highly durable and weather-resistant

Enhancing Energy Efficiency with Plastic Extrusion

Plastic extrusion technology plays a pivotal role in meeting modern energy codes. Multi-chamber profiles trap air, acting as thermal barriers that minimize heat transfer.

Durability and Weather Resistance of Extruded Plastic

Extruded plastic profiles can withstand harsh conditions, including UV rays, heavy rain, and temperature fluctuations. Additives and specialized coatings further boost durability.

Innovations in Plastic Extrusion Technology

Co-Extrusion Techniques

Allow combining different materials for enhanced profiles.

Digital Die Systems

Offer high precision and faster production turnaround.

Sustainability Advances

Incorporate recycled materials and improve overall environmental footprint.

Common Challenges in Plastic Extrusion and How to Overcome Them

- Warping: Use precision cooling techniques.

- Surface Defects: Maintain strict die cleanliness.

- Dimensional Inaccuracy: Implement tight process control and real-time monitoring.

Design Flexibility with Plastic Extrusion

Plastic extrusion allows intricate designs, making it easier to create aesthetic, functional profiles that meet custom architectural needs.

Environmental Impact of Plastic Extrusion

While plastic gets a bad rap, modern extrusion processes often incorporate recycled materials, reducing the overall environmental footprint. Proper end-of-life recycling strategies also help minimize waste.

Recycling and Sustainability in Plastic Extrusion

Recycled Content Integration

Many manufacturers now include post-consumer recycled materials in their extruded profiles.

Circular Economy Practices

Old window and door profiles can be re-extruded into new products, closing the loop in material use.

Cost-Effectiveness of Plastic Extrusion

Compared to metals and hardwoods, plastic extrusion offers significant cost savings—not just in material costs, but also in maintenance and longevity.

Thermal Performance of Plastic Profiles

Thermal break technology and multi-chamber designs enhance the thermal performance of plastic profiles, crucial for energy-efficient buildings.

Acoustic Insulation Properties of Plastic Extrusions

Multi-chamber profiles don’t just trap heat—they also provide excellent sound insulation, enhancing indoor comfort.

Case Studies: Successful Applications in Window Systems

- Residential Complexes: Enhanced insulation and aesthetic flexibility

- Commercial Buildings: Long-term durability and low maintenance

- Coastal Installations: Superior resistance to salt and moisture

Future Trends in Plastic Extrusion for Windows and Doors

Expect advancements in digital manufacturing, greener materials, and smart window systems integrated with extruded profiles.

Quality Control in Plastic Extrusion Manufacturing

Inspection Techniques

- Dimensional analysis

- Surface defect checks

- Mechanical property testing

Standards and Certifications to Know

- ASTM D4726 for rigid profiles

- EN 12608 standards in Europe

- Energy Star certification for energy performance

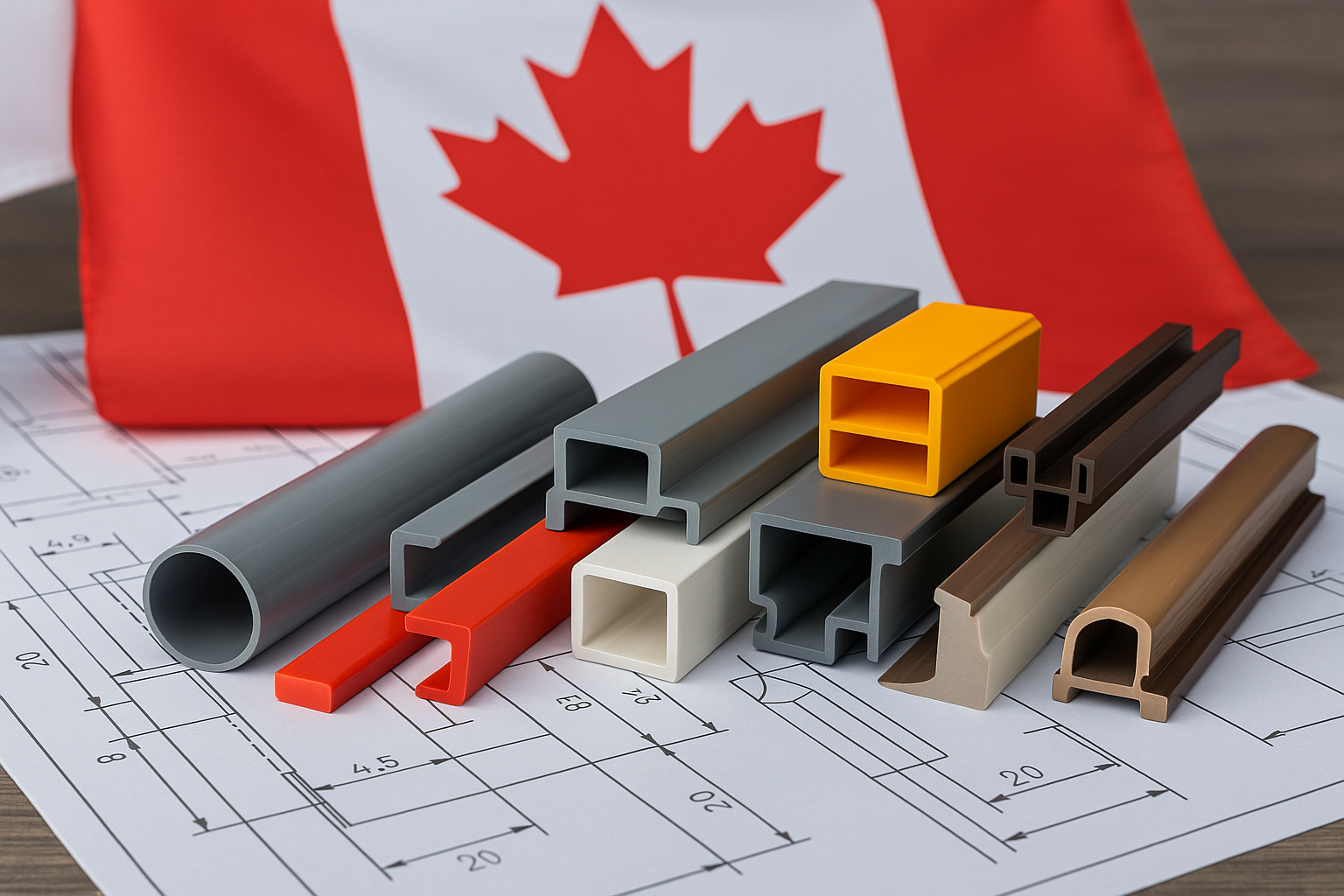

How to Choose a Reliable Plastic Extrusion Manufacturer?

- Experience and reputation

- Quality control measures

- Customization capabilities

- Compliance with industry standards

Installation Tips for Plastic-Extruded Windows and Doors

- Always follow manufacturer guidelines

- Use appropriate sealants and fasteners

- Regularly check alignment during installation

Maintenance and Longevity

Plastic-extruded profiles require minimal upkeep—just regular cleaning and periodic checks for seal integrity ensure decades of service.

Common Myths about Plastic Extrusion

- Myth: Plastic windows are weak.

- Fact: High-quality extrusions are robust and long-lasting.

- Myth: Plastic looks cheap.

- Fact: Modern finishes offer a premium aesthetic.

Customer Reviews and Market Perception

Increasingly, homeowners and builders appreciate the blend of aesthetics, performance, and sustainability that plastic-extruded windows and doors offer.

Innovations in UV Resistance and Color Stability

Latest extrusion technologies incorporate UV inhibitors and colorfast additives, ensuring long-term aesthetic appeal without fading or brittleness.

Final Thoughts: The Future of Plastic Extrusion in Building Design

Plastic extrusion for windows and doors is not just a trend. It’s a transformative force in modern building design. With rising demands for energy efficiency, superior durability, and customizable aesthetics, plastic extrusion continues to set new benchmarks in performance and sustainability. As technological innovations push the boundaries even further, builders and homeowners can expect even greater benefits from these advanced materials.

For those seeking industry-leading solutions and unparalleled expertise, Accord Plastics stands out as a top provider in the field. Their commitment to quality, innovation, and sustainability makes them a trusted partner for projects of any scale. Whether you’re retrofitting a home or embarking on a large-scale commercial build, Accord Plastics delivers precision-crafted extrusion profiles that meet and exceed expectations.

The future is bright and with the right materials and partners, your next build can be too.

Related Topic: How Plastic Extrusion Works | Fast, Efficient Process

FAQs

What is plastic extrusion used for in windows and doors?

It is used to create frames, seals, and profiles that enhance durability, insulation, and design versatility.

How long do plastic-extruded windows last?

With proper maintenance, they can last over 30 years, offering excellent durability and performance.

Are plastic-extruded doors environmentally friendly?

Many modern extrusions include recycled content and are themselves recyclable, making them eco-friendly.

How do plastic extrusion profiles perform in extreme weather?

They excel, offering superb resistance to UV rays, moisture, and temperature extremes.

Can plastic extrusion profiles be painted?

Yes, but many are produced in custom colors and finishes that negate the need for additional painting.

What certifications should I look for?

Look for compliance with ASTM, EN standards, and Energy Star certification for best-in-class products.